All tank designs and pipes in tank farms can be monitored with suitable leak detectors.

For optimum quality and resistance, we offer stainless steel or brass versions of the media-contacting parts as well as special solutions for hot-run tanks/pressure vessels.

For double bottoms of flat bottom tanks:

Basic technical requirements and information on leak monitoring of double bottoms of flat bottom tanks (requirements, connections, etc.).

For double-walled pipes:

DLR-G .. M: nitrogen-based with replenishment from connected nitrogen bottle

DLR-GS .. M: nitrogen-based, static, without nitrogen cylinder connected

DLR-P .. with dried air as leak detection medium

For upright cylindrical vessels according to DIN 6618/2 or similar:

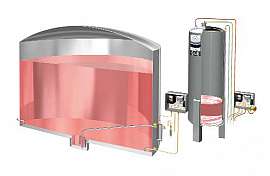

For horizontal cylindrical tanks according to DIN 6608/6616 or EN 12285:

SAMPLE APPLICATIONS:

Vacuum leak detector - double-walled bottom of a flat bottom tank

Vacuum leak detector - horizontal cylindrical container/tank

Pressure leak detector - underground double-walled pipe (monitored with nitrogen)